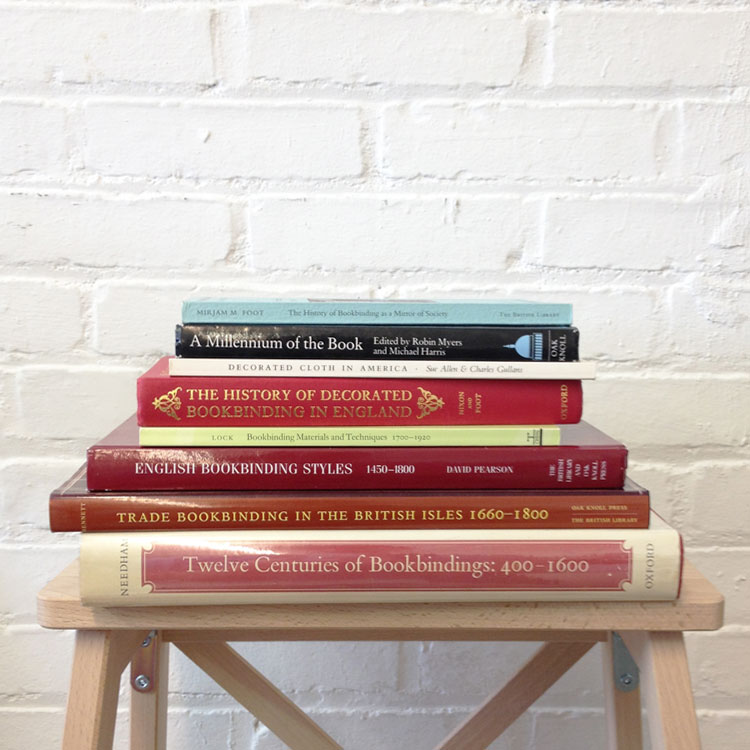

After reading through 1,275 pages of content detailing the history of bookbinding, I’m ready for my week-long course at the Rare Book School. For the following week, I’ll be spending my days at the University of Virginia in Charlottesville filling my brain with even more detailed information on the history of bookbinding! RBS was founded by Terry Belanger in 1983 at Columbia University as an institute to support the study of the history of books and printing and related topics for scholars and professionals working in these fields. RBS was moved to the University of Virginia in 1992.

I’ll be taking Introduction to the History of Bookbinding, which is a course that has been taught by Jan Storm van Leeuwen for over ten years. He is the retired Keeper of the Binding Collection at the Dutch Royal Library in The Hague. In his retired years, he continues to publish and lecture widely on the history of bookbinding.

While I’m in Virginia, the blog will be a bit quiet. Once I return to Boston, filled with greater bookbinding knowledge, you can look forward to a post about my experience at RBS.