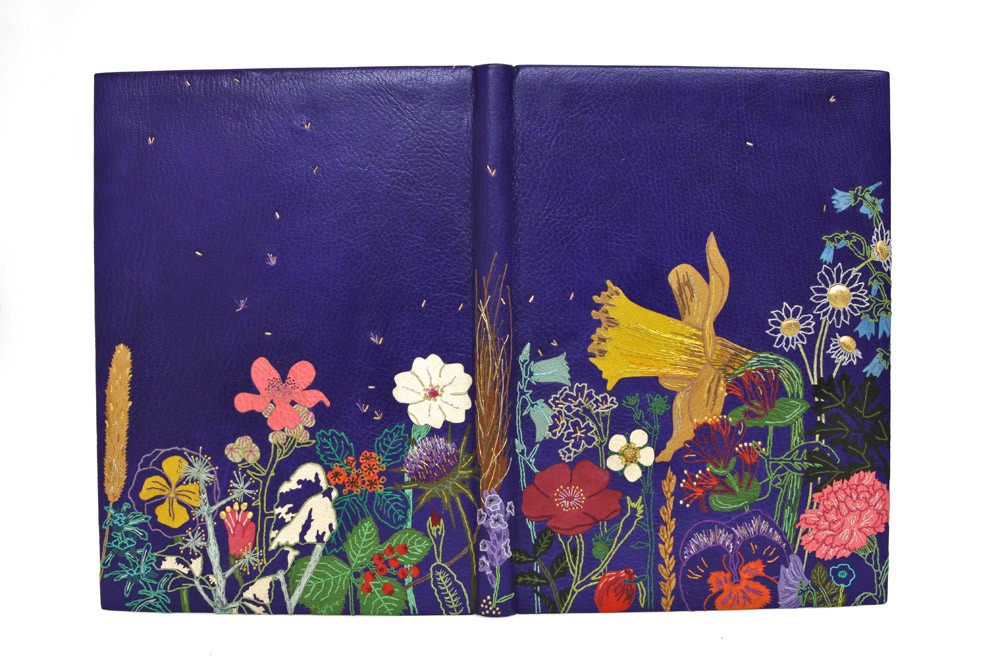

STORY OF THE TEXT: For his 50th birthday, my client, commissioned two pieces of music to be played during his celebration in Kenya. Each piece is inspired by two distinct features of Kenya, the Talek river and the nyatitis, an eight-stringed lyre instrument. As a commemoration of this event, he approached me to bind the sheet music into a full leather binding.

ABOUT THE BINDING: The sheet music came to me as 17 individual loose sheets. At the same time, the most recent The New Bookbinder (Volume 32) from the Designer Bookbinders appeared at our bindery. The journal contains an excellent and detailed article by Ingela Dierick titled Single Section Bradel Binding.

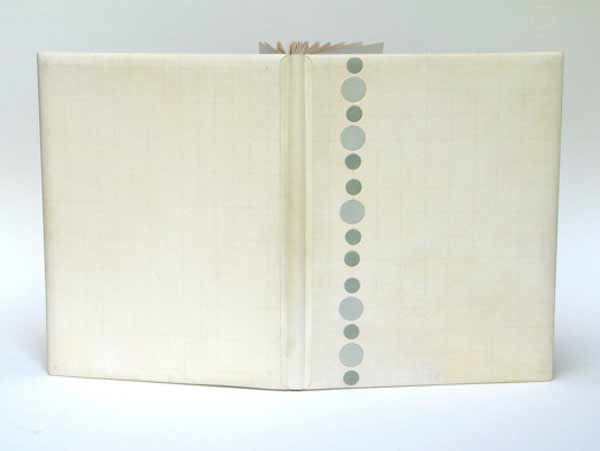

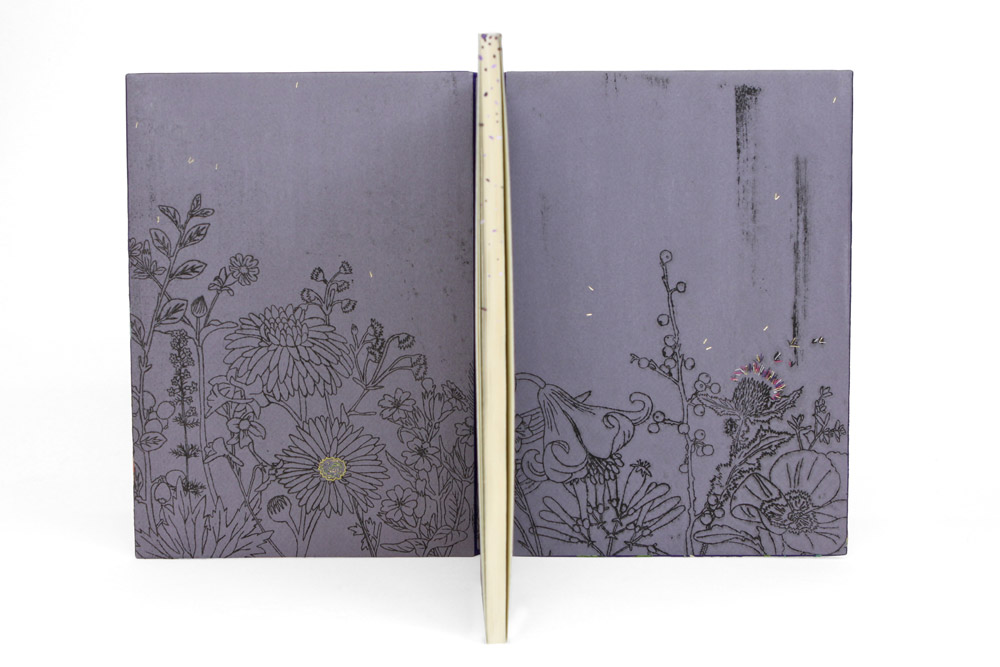

Using this article as a guide, I decided to guard the scores as a single signature. A single sheet of light green/gray Hahnemühle ingres was used to divide the two compositions. A single folio of the same ingres and a folio of pool blue handmade paper from Katie MacGregor was wrapped around the single signature to act as endpapers.

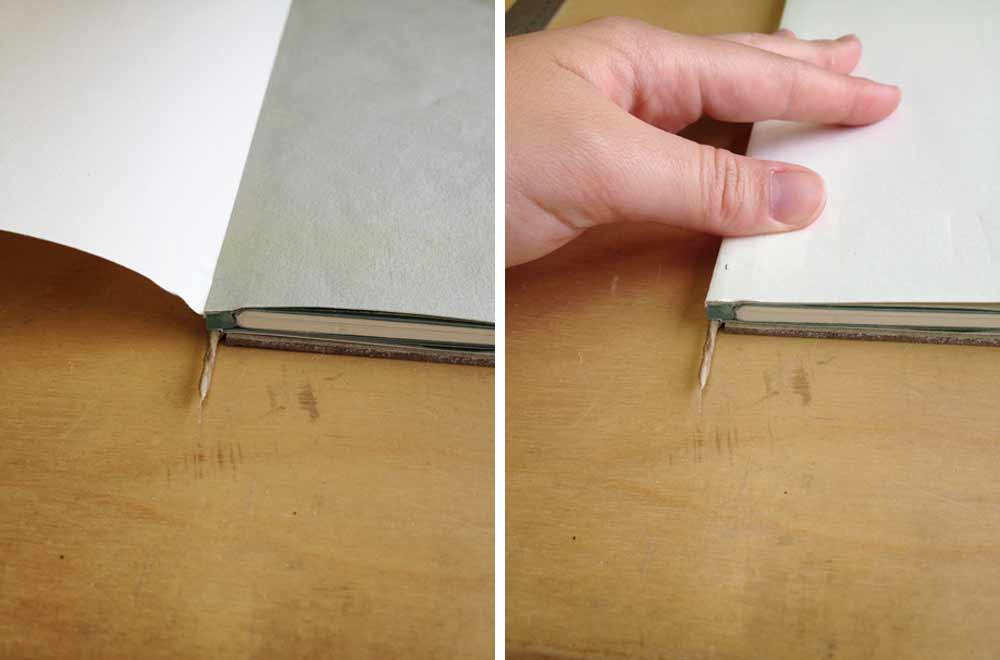

Once the signature was ready, I prepared a stub out of the same pool blue handmade paper to the thickness of the signature. The signature was pamphlet sewn to the stub, the layers of the stub were glued together using PVA and then put under weight until the next day. After trimming the text block and stub to size, I was ready to attach my final endpaper. A single sheet of waste paper was tipped onto the stub at the height of my shoulder. The waste sheet is then folded back and the endpaper is tipped onto the same position. The waste paper is then wrapped back around the fold of the endpaper. This creates a zig-zag and leaves a pocket for the false shoulder. This final endpaper will also act as the paste down and is a handmade paste paper designed by Deena Schnitman.

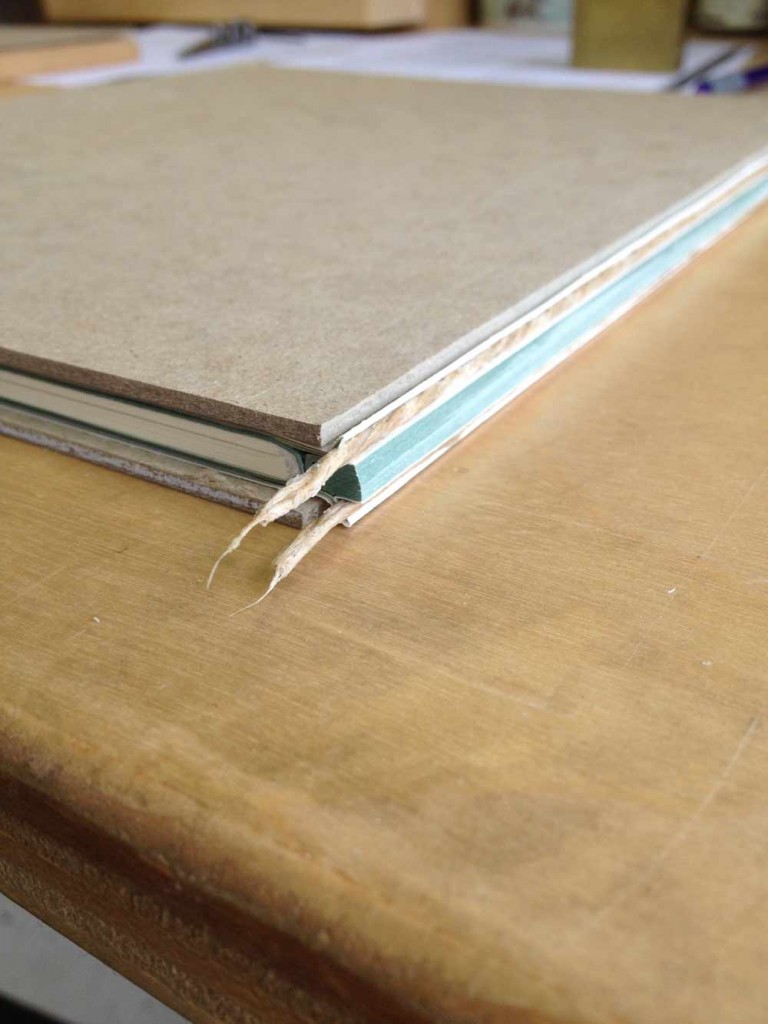

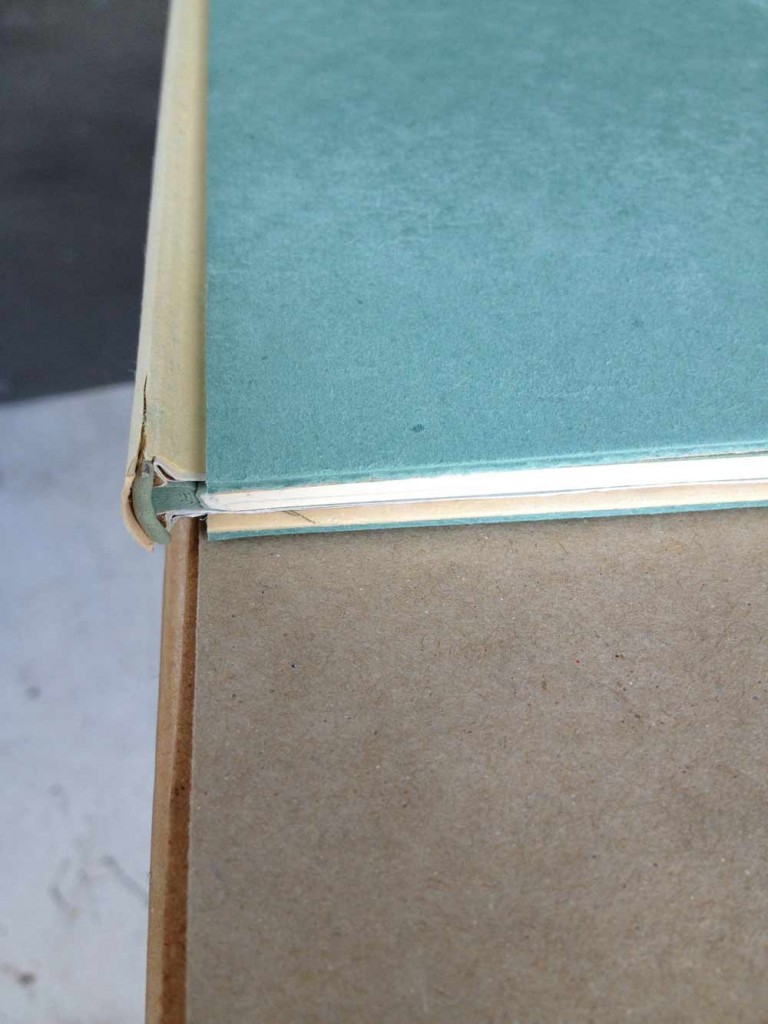

A false shoulder made from cord of appropriate thickness is tipped into the pocket between the waste paper that is tipped to the stub and where it wraps around the endpaper. The book is then placed into a press or job backer and the stub is rounded to create the shape of the spine and the shoulder. This is done with a bone folder and some force. From here I added the leather wrapped headbands and six layers of spine linings, which extend beyond the head and tail. Once the spine is dry, it is then sanded down smooth.

At this point, I attached a bonnet to the spine. The bonnet included a spine stiffener and was then slit to allow for the leather turn-in at the headcaps. Boards were laminated from 1.5 mm millboard and 20 pt. and attached to the waste sheet. The waste sheet was then torn off and smoothed down. Lastly, the boards were sanded to have a subtle chamfered shape.